Sample Preparatation Basics

The care that you take in preparing your sample mount is the most important factor influencing the data quality that will ultimately be obtained. A mount intended for SIMS analysis must be both flat and polished, with tolerances on the order micrometers. In general, it is the responsibility of the user to produce the required sample quality. Mounts arriving in Potsdam that are not of the required quality will be returned to the user for improvement, meaning in most cases that the date for the analyses will need to be rescheduled. Samples must be vacuum compatible to better than 10-6 Pa, and in most cases any necessary documentation of the sample (e.g., SEM images) or electron microprobe analyses should be conducted prior to sending your mounts to us.

For most projects samples will need to be in the Potsdam SIMS lab at least 7 days before the scheduled session. If the orientation of you sample is already defined (usually the case if you have done any imaging) you must make sure to make a small but obvious notch at the edge of each sample to indicate the north orientatation. Also, please scratch the sample number on the back side of each mount using a diamond-tip pen (or we will do this for you).

Possible Mount Geometries

Samples intended for analysis can consist of grain mounts, thin sections, or even polished rock disks or slices. The locations intended for analysis should be as close to the middle of the mount as possible. Materials for analysis in our SIMS facility can have the following geometries:

- 1" Diameter Rounds: The diameter of the mount should be between 24.5 and 25.5 mm, and the height of the mount should be no greater than 8 mm. It is best if the height is less than 4 mm tall, as this allows us to use springs to hold the sample in the sample holder.

- 10 mm Diameter Rounds: Sample diameter must be between 9.8 and 10.2 mm and sample height should be no greater than 3 mm.

- Flat Slices: The front and back of the sample must be parallel, allowing us to use springs to hold the polished surface against a metal face plate. The sample should be at least 5 x 5 mm in size, but no larger than 10 x 10 mm. This method is not recommended for isotope analyses requiring good analytical uncertainties.

Prior to analysis we will clean the sample in high-purity ethanol, gold coat the sample to make the surface electrically conductive, load the mount into a sample holder and will then image the sample using a flat-bed scanner (helps with the subsequent navigation).

When preparing multiple samples for a single mount, and especially if your will be requiring the measurement of point profiles, please position the samples so that the profiles are all run in the same direction. It greatly simplifies the measurement of profiles if they all run in the same directions (e.g., north-south or east-west on the mount's surface).

IMPORTANT: For isotope ratio analyses, and in particular for d18O determination where we strive for total uncertainties of around 0.1‰, all analysis points as well as the reference materials should be within 8 mm of the center of the sample mount. Target areas closer to the edge cannot be reliably analyzed due to deformation of the electric field caused by being too close to the edge of the sample holder.

Preparing Thin Section Mounts

Petrographic relationships often provide valuable information for augmenting isotopic data, hence thin sections are often the most appropriate sample type. Thin sections for SIMS analysis must be round and 25.0 ± 0.5 mm in diameter. As the SIMS primary beam penetrates only a few microns into the sample the thickness of the rock slice attached to the round piece of glass is not constrained, although retaining the 30 µm typical thickness for thin sections may help during the petrographic investigation. If the sample is more than perhaps 10 µm thick then it is important that the rock sample extends all the way to the edge of the glass -- failing to do so can result in the sample surface being tilted relative to the front of the SIMS sample holder.

A disadvantage of thin section style mounts is that it is difficult to insert reference materials into them, meaning that this might not be the preferred sample geometry when very good analytical uncertainties are reqeuired. Again it is stressed that areas intended for analysis should be near the center of the thin section.

Preparing Grain Mounts, in Particular Zircon Samples

In order for us to provide the best possible data for your project, grain mounts must be carefully made. In many cases (e.g., zircon U-Pb, d18O analyses) the reference material should be embedded in each 1-inch mount. It is essential that the mounts be flat, well polished and free of bubbles; it is important to pay close attention to assure that the epoxy resin makes good contact with each grain without any trenches forming between epoxy and the individual grains. It is also important that prior to doing your SIMS analyses you should obtain backscattered electron (BSE) and cathode luminesence (CL) images of each grain in order to improve the targeting of the SIMS ion beam. When taking such images with a scanning electron microscope you sould use the minimum electron beam current and the fastest scan rate which are compatible with getting the necessary information. Slow scanning and a high electron dose can damage the epoxy resin in which the zircons are mounted, and this can cause problem during the U-Pb analytical session.

We recommend that you contact us before beginning any sample prep work so that we can help you obtain the best possible data quality from the Cameca 1280.

For information regarding which types of embedding materials (epoxy) one might best use, we refer you to a detailed study by the Edinburgh SIMS facility.

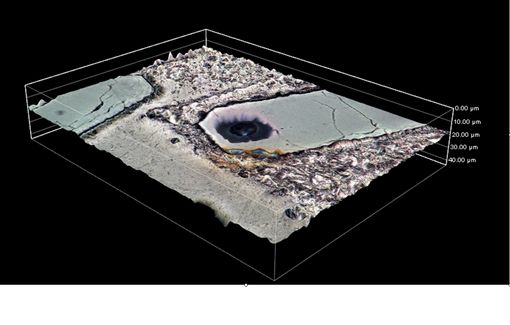

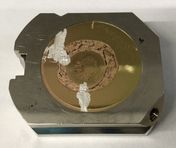

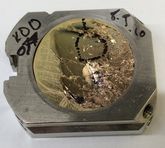

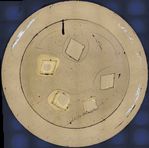

How Not to Make a SIMS Sample Mount

The following photo gallery shows examples of poorly made SIMS samples that have arrived in Potsdam. These are meant as examples of how your sample should not look. Click on the indvidual photos to get an enlarged view and a more detailed figure caption.